This document defines and covers the methods for installation of Water Supply Piping System at a construction project site, in compliance with the approved designs and approved material submittals.

Prior to installation of PPR & PEX Water Supply Piping System, the supervisor and foreman will verify and ensure that all the safety requirements have been complied.

He will verify that all relevant approved latest revisions of shop drawings, technical submittals, inspection and test plans are in the work place for installation reference.

In process works shall be monitored for quality of workmanship and installation against approved construction drawings by the relevant Site Engineer, Supervisor and QA/QC Engineer.

Below is list of necessary tools and equipment:

- PPE for all staff and labor

- Measuring tape and setting out markers

- Electric Drill hammer

- Pipe Fitters tool box

- Step Ladder / Scaffolding

Storage & Handling of PPR & PEX Pipe Materials

To ensure that deterioration of the material does not occur during storage, it is imperative that the following recommendations are adhered to:

Storage of piping material shall be on the elevated racks minimum 300mm above the ground level.

PPR pipes should be stored on a well spaced and secured area which separates the material from other stored equipment to avoid mixed up and accidental clashing with other materials which may result to damage.

PEX & PPR pipes should be protected from weather elements by means of placing tarpaulins or similar sheets over them securely fixed to the timber support posts.

Pre Installation Requirements

The supervisor and foreman will orient and familiarize all the plumbers and labors involved in the installations regarding the relevant approved shop drawings, technical submittals, installation procedures and details, acceptance criteria and safety requirements.

Supervisor and foreman will examine surfaces to receive water supply system works for compliance with installation tolerances and other required conditions, as described in the installation requirement. Installation will not proceed until unsatisfactory conditions have been corrected.

All installation / Construction / Testing works shall be carried out in compliance with the contract specifications and project health and safety manual.

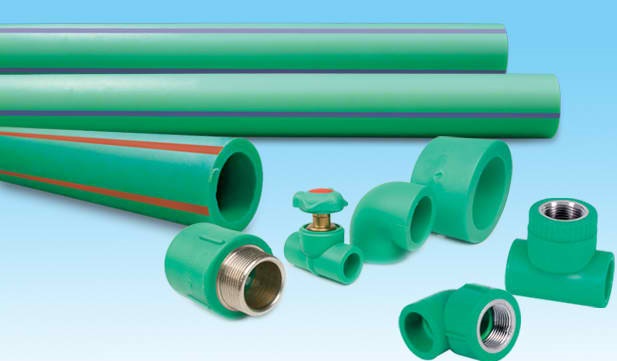

Installation of PPR Water Supply Piping System

Unless otherwise specified, all installation shall be according to the approved shop drawings and contract specifications.

Drawing plans, schematics, and diagrams indicate general location and arrangement of water supply piping system.

Install piping as indicated unless deviations to layout are approved on coordination drawings.

Identify and survey pipe routing at site according to approved shop drawings. Floor finish level reference line shall be marked on nearby RC column or wall for checking on bottom of pipe level.

After identifying actual pipe routing, install concrete anchor and hanger rods at both ends of straight pipe section.

Tie a thread between both hanger rods at the straight pipe section and adjust height of thread to bottom of pipe level of PPR pipes to be installed.

Cut hanger rods with cutting wheel machine to the required length and install hanger rods for PPR pipe as per the following:

|

PIPE DIA IN mm |

SUPPORT INTERVALS IN mm |

|

20 |

1200 |

| 25 |

1400 |

|

32 |

1600 |

|

40 |

1800 |

|

50 |

2050 |

| 63 |

2300 |

| 75 |

2450 |

|

90 |

2600 |

|

110 |

2900 |

| 125 |

3200 |

|

160 |

3400 |

| 200 |

3450 |

| 250 |

3500 |

Install concrete anchors and pipe hanger brackets and adjust level of pipe bracket to the required bottom of pipe level.

Measure length of PPR pipe required to be cut and mark cutting position on pipe with template & marker pen. Cut PPR pipe using cutter or fine tooth saw. Clean all burrs of the pipe by using a file after cutting.

Install pipe on pipe hanger and fasten fasteners on pipe brackets and hanger rod. Check and ensure that pipe is securely supported on hanger brackets. All scaffolding and ladders used for installation of ppr pipes at high level shall be erected according to safety guidelines.

Ancillary items such as PRV station, valves & the like shall be installed using appropriate adaptor fittings. All valves shall be provided with union joint to allow for proper installation / future dismantling.

Install identification labels as per project requirements.

Jointing of PPR Pipe (Electro Fusion Welding)

Cut the pipe at right angles to the pipe axis. Only use Fusiotherm pipe cutters or other suitable cutting pliers. Take care that the pipe axis is free from burrs or cutting debris and remove where necessary.

Mark the welding depth at the end of the pipe with the enclosed pencil and template.

Mark the desired position of the fitting on the pipe and/ or fitting.

Position the fitting with even air gap around the circumference.

Regulate fusion equipment for the right fusion parameter.

Compare the indications of the fusion equipment with the parameters of the label.

Do not move or stress the pipe and fitting during the whole fusion process and cooling time. The minimum required welding & cooling time is as per the following data table:

|

Pipe Dia. (mm) |

Welding Depth

(mm) |

Heating Time

(sec) |

Welding Time

(sec) |

Cooling Time (min) |

|

20 |

14 | 5 | 4 | 2 |

| 25 | 15 | 7 | 4 |

2 |

|

32 |

16.5 | 8 | 6 | 4 |

|

40 |

18 | 12 | 6 |

4 |

| 50 | 20 | 18 | 6 |

4 |

|

63 |

24 | 24 | 8 | 6 |

| 75 | 26 | 30 | 10 |

8 |

|

90 |

29 | 40 | 10 | 8 |

| 110 | 32.5 | 50 | 10 |

8 |

Once the fused joint is ready the pipeline shall be pressure tested with water up to 10 bar and after no leak is observed it shall be offered for inspection to consultant for approval prior to application of insulation.

Install Water hammer arrestor only after approval of pressure test inspection from consultant.

Pex Pipe Installation Method – Concealed On wall/ Slab

All final equipment connections to sanitary ware shall be with PEX pipes installed within flexible conduits chased in wall & floor screed between SSL & FFL.

Floor finish level reference line shall be marked on nearby RC column or wall for checking height of concealed pipe.

Wall tiles setting out line has to be marked for checking on concealed pipe position.

Based on the floor finish reference line and wall tiles setting out line, identify conceal pipe routing on the wall based on approved Construction drawing. Mark position of channel required to be cut on wall by using thread marker.

The marking of the channel to be cut on wall must be at least wider than outer diameter of pex pipes. Use spirit level to check on the vertical and horizontal marking on wall to make sure that the marking is aligned vertically and horizontally.

After marking of pipe routing, identify depth of wall cutting required to conceal Pex pipes. The depth of channel cutting shall be adjusted to the required wall finishing thickness. Use electric hand diamond cutter and start cutting wall based on the marked pipe channel position.

Hand chisel shall be used for chiseling of channel after cutting of grooves by using diamond cutter.

All wall /slab cutting & chipping works to be done by main contractor.

Measure length of Pex pipe required to be cut and mark cutting position on pipe with marker pen and thin metal sheet. Cut Pex pipe to required length by using pipe cutter or fine tooth saw.

Install Pex pipes and fittings onto the cut channel and apply cement plaster on top of pipe to hold pipe in position.

All pipe joints shall be left exposed until pressure test on Pex pipe has been completed.

Adjust the Pex pipe draw-off points to level with the wall finishing level.

Pex piping shall be connected to PPR piping for pressure test.

Pipe work from water tank up to suction of the transfer pumps shall be UPVC Pressure Pipes & Fittings manufactured according to BS 3505 Class E, but from water tank to suction of Fire pumps shall be hot dipped galvanized steel.

Pressure Testing of PEX & PPR Piping System

All draw off points have to be plugged with stopper and shut off main valve to section of PPR pipe to be tested.

Connect pressure gauge to the lower section of water supply pipeline.

Start filling in water into pipes by using hand pump. The valve located at higher section of the pipe has to be opened periodically to release air out from the pipeline network when water is being pumped. Subject piping to static water pressure of 1.5 times of operating pressure (150 psig/10 bar) without exceeding pressure rating of PEX & PPR pipe.

Maintain the pressure inside the pipeline for 4 hours and inspect for leakages at pipe joint and pipe body. The final pressure reading at the pressure gauge should not drop more than 5% from the initial test pressure.

Once water test has been successfully carried out, remove all stoppers and drain off water from the pipeline.

Cover all open ends of pipes and fittings to prevent debris from going into pipeline.

Inspection Checklist for Installation of Water Supply Piping

Check the material used for installation is approved, correct type & size.

Check that the installation is as per approved shop drawing

Check the elevation and orientation are correct

Check the installation is perpendicular or horizontal to wall in neat manner

Check that the pipework is well supported

Check the pipework is not obstructing or clashing with other services

Check the joints are made perfectly

Check if the pipework is ready for testing

Check if the installation is as-per approved shop drawing and manufacturer’s recommendations

Discover more from Method Statement Store

Subscribe to get the latest posts sent to your email.