This as built procedure describes the requirements for preparation of as built drawing and other project as build documentation.

The purpose of this procedure is to ensure that variations from the original dimensions, design intent or materials shown on the drawings, specifications, or other documents are appropriately recorded for the purpose of producing accurate as built drawings and documents.

This procedure can be implemented in coordination with other procedures like:

- Engineering Drawings Procedure

- Procedure for Design Change and Clarification

- Engineering Document Control Procedure

- Project Completion Planning Procedure

The following personnel have responsibilities mentioned in this procedure:

- Project Engineering Manager

- Project Manager

- Consultants, Subcontractors, vendors, manufacturers, project staff Owner/ Client Representative

- Consultants Engineer Qualified Persons

As Built Procedure

As built drawings and documents are an essential record of the end product of the Project’s activity. The sections below describe the process to follow:

The project Engineering Manager is responsible to prepare a list of the required ss build documentation and shall advise the Consultants, Subcontractors, Vendors, Manufacturers and Project staff of their responsibilities under this procedure.

Project Engineering Manager is also responsible to collate all the As Built information received and shall coordinate the preparation of the project as built document.

The document controller is responsible for the proper management storage and distribution of these as buil documents.

As-Built Process Flow

All As-Built documentation shall be compiled and presented by amending the construction drawings, specifications or material schedules in sufficient detail to reflect the actual condition of the finished product. The As Built document are historical documents prepared for future reference and shall therefore reflect the project conditions and specifications as they exist at the time of project completion.

The Project Engineering Manager is responsible to ensure that the details and dimensions for ‘built-in’ and covered up work shall be recorded whilst work is open for inspection.

As Build Document Formats

The As-Built document number consists of the original drawing number and the next available revision number. The revision history box is annotated to show that the document is an As-Built record. If subsequent revisions are required, the next revision number is assigned.

Each set of As Build documents is a packaged set comprising face sheet, description and contents for submission to the Owner/ Client.

Where Existing Facilities have been modified, any requirements for the production of As-Built documentation for such modifications shall be clearly defined.

All As-Built drawings shall be in accordance with the Project Engineering Plan and procedure For engineering drawings.

As Built Drawing Contents

The information that is typically recorded when producing As Built documentation and drawings includes, but is not necessarily limited to, the following:

- Levels of various elements and foundations

- Horizontal and vertical locations of underground utilities and appurtenances referenced to permanent surface features or grid lines. The coordinates (x,y,z) at each change point of all services shall be recorded at each service crossing location and change of direction.

- Location of internal M&E Services, utilities and appurtenances including works concealed in during construction. Locations shall be referenced to visible and accessible features of the work.

- Major field changes to dimensions and details of items which may be critical to the end user and / or which cannot be readily identified following completion of construction.

- All M&E Equipment shall be identified and numbered / labeled in accordance with the project specifications and listed in suitable equipment schedules listing all necessary technical data etc.

- All maintenance access doors / points, test points, maintenance withdrawal spaces for plant and equipment, safety interlocks etc.

- All valves, isolators etc. shall be clearly identified and labelled and locations correctly referenced.

- Where required by the project specification and or statutory requirements, any necessary laminated and framed As-Built drawings detailing the M&E services shall be provided and fixed to the M&E plant-room walls.

Method of Recording site as build status

At the end of each work package, the Project Engineering Manager shall instruct the Consultants, Sub-Contractors, Vendors, Manufacturers and Construction staff to prepare the first draft of As-Built Documentation.

The documents shall be upgraded to the next revision with ‘Draft As-Built’ in the revision column.

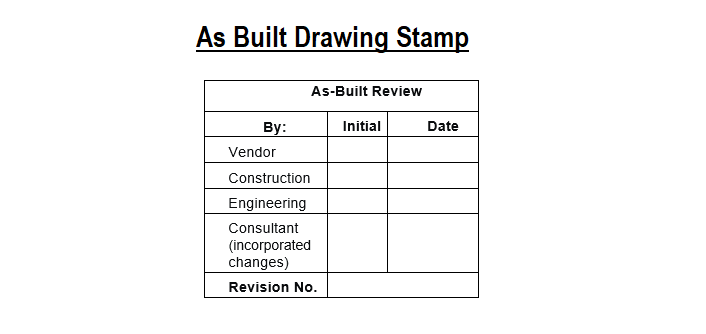

On receipt of the documents, the Document Controller shall distribute the documents in accordance with Engineering Document Control procedure with the ‘As-Built Review’ stamp endorsed for each section’s review (see Appendix A as built drawing stamp).

The Project Engineering Manager shall review the Draft As-Built Documents for completeness and mark-up the documents if necessary and initial the review.

Where required or appropriate the as Built documents shall be reviewed by the Consultant Engineer.

The monitoring of the progress of the ‘As-Built’ documentation shall be in accordance with procedure for engineering documentation control.

On completion of the reviews, the As Built documents are returned to Consultants, subcontractors, Vendors, Manufacturers and Construction staff for their updates as per the ‘marked up’ comments.

The Final As-Built documents shall be submitted with the latest revision status and ‘AS BUILT’ for the description in the revision column.

The Final prints shall be endorsed by the respective Qualified Persons as per the requirements of the Project Engineering Plan.

The number of sets (hard copies and soft copies) shall be in accordance with the procedure for project completion.

Client Submission of As Build Document

The Project Engineering Manager or the Project Manager shall then submit the completed As-Built documentation to the Owner / Client Representative and will include the same in the operation and maintenance O&M Manuals.

Outside Suppliers

The project Consultants, Subcontractors, Vendors and Manufacturers are responsible to ensure that all As-Built changes are recorded accurately as required under procedure of design change and clarification.

The Project Engineering Manager is responsible to ensure that subcontractors and Vendors produce and submit completed, checked, thorough and accurate ‘As-Built’ documentation.

Relevant Records

- Required As-Built documentation list

- As-Built drawings/documents

- Final prints

Appendix A ‘As-Built’ Review Stamp

| As-Built Review | ||

| By: | Initial | Date |

| Vendor | ||

| Construction | ||

| Engineering | ||

| Consultant

(incorporated changes) |

||

| Revision No. | ||

Discover more from Method Statement Portal

Subscribe to get the latest posts sent to your email.