This electrical method statement covers the nature and type of work for the Earthing & Lightning Protection System installation as per site requirements for the project.

The piles and vertical re-bars are provided with connections for Earthing & Lightning Protection System installation by main contractor.

Any core drilling, chipping, excavation and back filling work required for the fulfillment of this Method Statement is under the scope of Main contractor.

This statement also covers frequency of which the inspections are to be carried out.

All documentary requirements for this purpose shall be submitted for approval and this shall include manufacturers data, certificate of compliance, brand designation, type and class including samples.

Necessary Tools & Equipment

- Cutting Tools

- Acetylene Set

- Standard Electrical Tool Box

- Screw Drivers

- Flat Files

- Measuring Equipment’s

- Hand Gloves, Fall Protection Equipment’s (and other personnel protective equipment’s as necessary)

- Ladders / Scaffolds

Earthing System Installations

Ensure all relevant shop drawings are approved and available to the installation team.

Earth and Equipotential Bonding System:

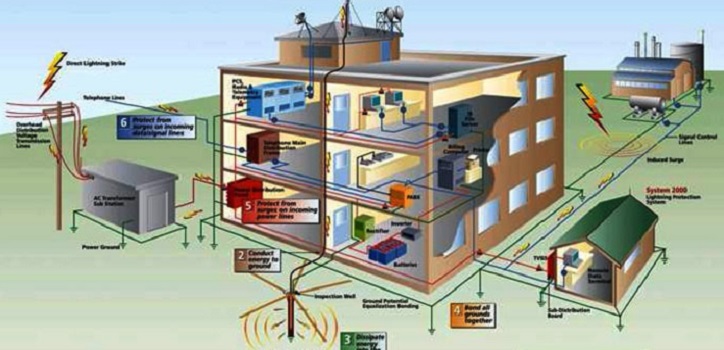

Earth System serving the whole building shall adopt the pile reinforcing bars, also forming part of the Lightning Protection System, as the primary earth electrodes.

Main Telecom Rooms (MTR) shall have primary earth connections via the re-bars of the columns adjacent to the room.

All other plant rooms will have exothermic welded re-bar connections terminating in a column facing connection, plate will be provided on each column as per site condition and will be the primary connection points to the earth pit network.

The center star point of each Transformer and stand-by Generators shall have dual independent connections to earth bars. In case the utility wish to lower the transformers earth impedance, additional exothermic welded re-bar connections as described above will be provided. For generators, additional exothermic connections will be made to a main building earth ring.

Earth bars will be provided within each Telecom Room as described above. Connection barriers shall be provided where sensitive electronic equipment requires an earth reference.

For other plant rooms not located directly in contact with columns, earth cables wired back to the main earth bars in the basement switch rooms will be their primary earth connection.

Attached to the basement LV cable distribution system, a ring network consisting of 70 mm2 insulated cable network will be installed with exothermic primary connections to each main HV switch room, LV switch room and technical plant room main earth bars.

Earth bars will be installed above the whole length of each switchboard. The same will be provided in each riser in proximity of the landlord distribution board.

Functional earth bars will be provided within comms room and functional earth bars to general earth bars (integrally) will be provided within each distribution board, composite distribution board assembly and PDUs.

Earthing bars of main distribution boards are to be connected, by bare earthing conductor, directly to main earthing bar at main distribution room and by protective conductor run with incoming feeder from respective supply point.

Distribution, lighting and power panel boards are to be connected by protective conductors run together with incoming feeder cable, connecting earth terminals in panel boards with respective main distribution board earthing bar.

Socket outlets are to be earthed by protective conductor looped around with the branch circuit and connected to earth terminal within socket outlet box and to which socket outlet terminal is to be connected.

Final ring sub circuits: protective conductor of every final ring sub circuit is to be in the form of a ring having both ends connected to earth terminal at origin of circuit in panel board.

Lighting fixtures and other exposed conductive parts of electrical installations, such as switches, heaters, air conditioning units etc. are to be connected by protective earth conductors to earthing terminals of respective panel boards.

Conductors are to be securely fixed recessed in floor grooves or niches, or fixed to walls by appropriate staples. Earth bar or loop is to be securely fixed to building wall with copper or brass saddles.

Earthing conductors are to follow shortest path between earth rods and main earthing terminals or bars, and are to run in PVC conduit (duct) fastened to building structure by approved supports and extending 0.2 m above level, and are to be protected against mechanical damage and corrosion.

Protective conductors: separate protective conductors, which are not part of a cable, are to be fixed on same support or drawn into same conduits as circuit conductors.

Protective Bonding: remove any non-conductive paint, enamel or similar coating at threads, contact point and surfaces and ensure that bonding is made by fittings designed to make secure bonds.

Protection against corrosion: protect bolted connections against corrosion either by filling with Vaseline or coating with a special anti corrosion compound and proper capping.

Connections: where earth connections between dissimilar metals must be made by using bimetallic fittings and protect by coating with moisture resisting bituminous paint or compound, or by wrapping with protective tape to exclude moisture.

Tighten screws and bolts for grounding and bonding connectors and terminals according to manufacturers provided torque-tightening values. If manufacturers torque values are not indicated, use those specified in applicable standards.

Lightning Protection System Installations

Prior to installation ensure all relevant drawings are approved and available to the electrical installation team.

Also ensure all relevant approved materials like rod, bar, copper tapes, cables and fittings are arranged by the installation team.

Ensure the compliance with all safety requirements as per safety plan and risk assessment.

The network of approved size bare copper tapes shall be installed across the roof area as per approved drawing.

All exposed metal work including structural steel work on the roof of the structure and metal which is in the safe isolation distance shall be bonded to the network with copper strip and purpose made clamps.

Any extended metal running through the structure or with the structure within the isolation shall be bonded at the top and bottom to the lightning protection conductor system with copper strips and purpose made clamps.

Bonds shall be made of the same material as the main lightning conductor network, except where they are installed direct in the ground when they shall be copper strip. Under no circumstances shall an aluminum strip be installed direct in to the ground.

The copper strip to be installed in raft of the building as per approved drawing and to be connected to the pile reinforcement bar by PVC single core wire with the U clamp.

Installation Procedure / Work Sequence

Installation of Earthing & Lightning Protection will be coordinated with other system and structural components as per approved shop drawing and material submittals.

Unroll the required length of copper tape smoothly.

Bare hard drawn copper tape of 25mm x 3 mm (W x T) will be connected to the earth stud (which are already connected to re-bars inside the concrete columns from Basement to Roof floor level). Connect the copper tapes from earth stud to earth bars.

Bare hard drawn copper tapes shall be supported by means of approved ‘B’ bond clamps and will be rigidly supported in the reinforcement steel structures.

Use Flexible copper braid for bonding gates, doors, fences etc.

All equipments which are installed will be connected to the earth bars with copper tape of size 25mm x 3 mm (W x T) as per approved shop drawing.

Use power drill machine and make holes in columns and concrete with an interval of 1200 mm in straight lines parallel to walls. Ensure re-bars will not be cut during drilling.

Insert rawl plugs into the screw hole.

Fix the non-metallic DC tape clips in location where the top part is in open position.

Place the copper tapes on top of the non-metallic DC tape clips.

Tighten the screws adequately and close the non-metallic DC tape clips.

Multiple Point Air Terminals on 1000mm Air Rod conductors 12mm dia will be connected to the vertical down conductor using 12mm thread diameter Air Rod Base.

All lightning protections from the roof shall be connected as per approved shop drawing.

General Site Safety Requirements

All the Employees coming to the Project (including the Visitors, Drivers. Etc…) must attend the Safety Induction Training conducted by safety team.

Ensure a Safe Working Area that include but not limited to; Appropriate Access and Egress, Adequate Lighting and Ventilation, Appropriate Working Platform etc.

Arrange the appropriate PPE’s and ensure its correct usage by the worker while working.

Wear the appropriate PPE’s in addition to the Basic PPE’s that includes the hard hat, high visibility jacket, overall and safety shoes.

Arrange appropriate power tools and hand tools.

Ensure Adequate Power Supply through an Isolating Device.

Maintain Housekeeping “Everything has a place and everything in its place”.

Always keep the access / egress clean and tidy.

Site engineer to ensure the compliance with the safe system of work procedures and arrange the resources. Supervisor/ Foremen will closely supervise all operations and Site Safety team will monitor the activity.

Inform all the Accidents and Near Misses to the Safety Team without any time delay.

Get the awareness about the location of the Site First Aid Clinic, Fire Points and the Nearest Assembly Points prior to start the work.

Get the Permit to Work before work commences if it is required as per the Site Safety Rules and Regulations.

Always remember “You alone be responsible for your action; so if in doubt ask your supervisor and do not put yourself at danger”.

Discover more from Method Statement Store

Subscribe to get the latest posts sent to your email.