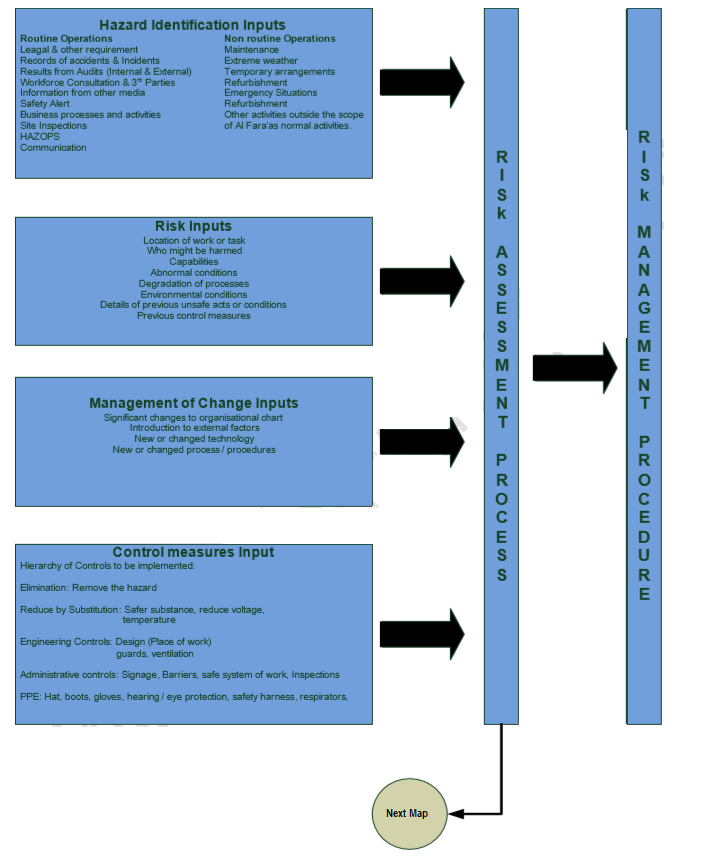

Below is a steps wise risk management process that consists of hazard identification, risk assessment, risk control, analysis and improvement.

The overall responsibility for the implementation of this procedure is with the project manager and safety and other department heads.

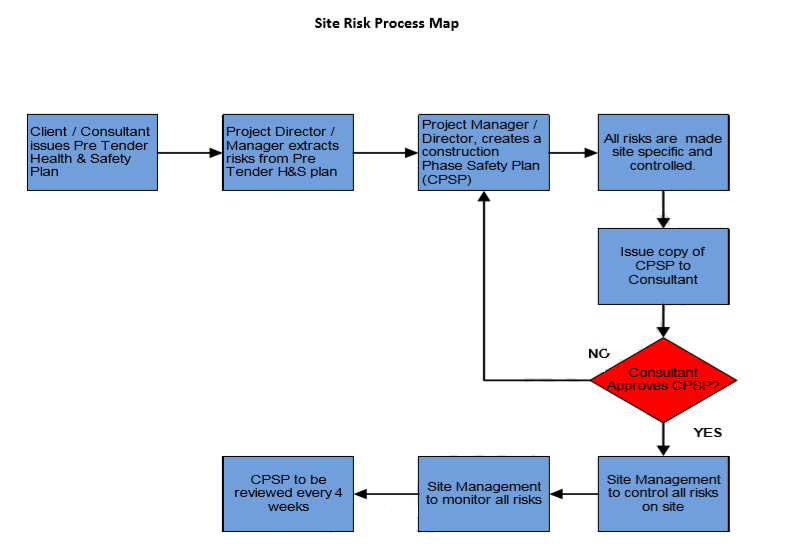

Below are three flow charts that are helpful to understand the process of health, safety and environmental risk management on a construction project.

Risk Management Process Flow Chart / Map

Risk Assessment Process Map

Site Risk Process Map

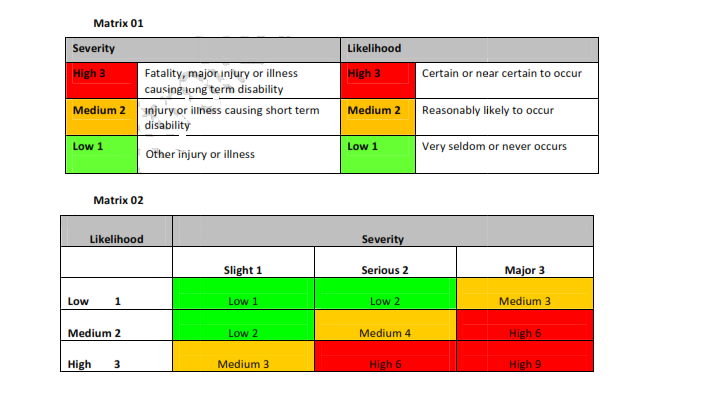

Risk Determination

For each hazard identified, the corresponding risks and persons at risk are recorded and a risk rating is given both for normal and abnormal operations.

The risk is determined by assessing:

- The potential severity of harm / damage;

- The likelihood that harm / damage will occur

Once the risk has been determined then a high, medium and low methodology will be used 1 low, 2 medium and 3 high.

Severity of Harm

In order to assess the severity of harm following issues should be considered in relation to the relevant work activity:

• The part(s) of the body likely to be affected;

• The nature of the harm, ranging from slight to extremely harmful:

Slightly harmful (e.g. superficial injuries, minor cuts and bruises, nuisance and irritation, temporary discomfort etc);

Harmful (e.g. lacerations, burns, concussions, deafness, dermatitis, ill etc);

Extremely harmful (e.g. amputations, major fractures, poisonings, fatal injuries, severely life shortening diseases, acute fatal diseases etc).

Likely Hood of Harm

When establishing the likelihood of harm which ranges from highly unlikely to likely, risk control measures already in place as well as hazard specific legal requirements, codes of practice or guidance from manufactures / suppliers as well as information from previous accidents / incidents need to be considered.

Use matrix to identify and give a priority rating for each Health & Safety Hazard.

Risk criteria

After the score and rating has been defined, High, Medium or low, as per above matrix, then reduce the level of risk as per the below matrix.

Risk Control

When deciding on risk controls, the control of hierarchy must be implemented to reduce the risk to as low as reasonably practicable (ALARP).

Risk Monitor

All risks on project site will be monitored on a daily, weekly and monthly basis. Daily observations will be conducted and recorded on observation sheet.

Weekly inspection will be conducted and recorded on Weekly Safety Inspection and will be signed off by the project director / Safety manager.

Documentation

All risks shall be documented on risk assessment form.

If method statement is required for safe system of work then it shall be required as per approved format.

A company risk register will identify the majority of the generic risks of its activities on risk register.

The Construction Phase Safety Plan (CPSP) shall be created to manage all aspects of health and safety on project sites.

The CPSP shall be reviewed not exceeding four (4) weeks from the last reviewed date, and recorded on Construction Phase Safety Plan Review form.

Daily observation will be recorded on to daily observation register.

Weekly site inspection will be recorded on Weekly Safety Inspection.

Audit & Performance Analysis

In accordance with the internal audit procedure, internal audits shall be conducted at pre-determined intervals to monitor compliance with this procedure.

Non-conformance shall be recorded and analysed to determine trends and areas for improvement.

Associated Records

The following records are maintained and are archived for a minimum of 5 years after completion of the project.

Risk assessment Form

Company Risk Register

Construction Phase Safety Plan

Construction Phase Safety Plan Review

Daily Observation Report

Weekly Safety Inspection Report

Discover more from Method Statement Portal

Subscribe to get the latest posts sent to your email.